Fixing or installing a bore pump is an essential task for ensuring a reliable water supply, especially in rural or agricultural areas. Bore pumps draw water from underground sources, supplying it for irrigation, livestock, or domestic use. Whether you’re repairing an existing pump or installing a new one, proper steps and care are critical to ensure optimal performance.

When installing a bore pump, the first step is to select the right pump for your needs. Submersible pumps are typically used for deeper bores, while jet pumps are suited for shallow applications. Accurate measurements of the bore depth, water levels, and required pressure are essential to choosing the correct pump size and type.

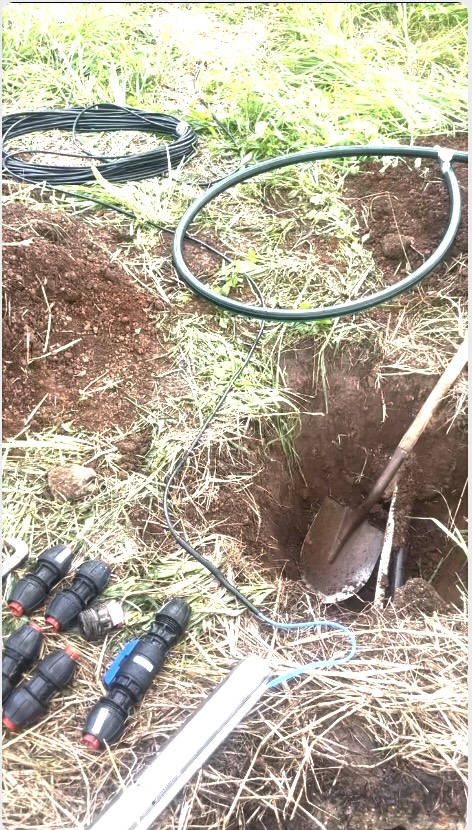

The installation involves securely lowering the pump into the bore, connecting it to the power supply, and ensuring all pipework is properly fitted and sealed. Once installed, thorough testing is necessary to confirm the pump operates efficiently without air leaks or blockages.

For repairs, common issues include motor failure, clogged filters, or worn-out components. Diagnosing the problem involves testing electrical connections, inspecting pipes, and checking for blockages. Regular maintenance is vital to extend the life of the pump, including cleaning filters, lubricating parts, and monitoring performance. Properly handled, a bore pump ensures a consistent water supply for years.

Check out our Video on facebook with the details.